Components for classic cars out of a modern 3D-printer? 🤔

RPG Industries, Inc. is always looking for ways to stay cutting edge in a saturated industry. The team decided to bring in a Markforged Metal X system and a Mark Two professional-series 3D printer, which they have used for a wide range of applications.

With additive manufacturing, they were able to print a vintage carburetor cap, which could not be sourced anywhere in the world. They first prototyped it using Onyx and then printed the final part out of 17-4 PH Stainless Steel.

What kind of part would you 3d print? Write it in the comments ⤵️

CNC Machine Shops are increasingly turning to Metal Additive Manufacturing to create additional revenue streams while fostering innovation. Machine shops that traditionally “only” offered machining relying on 2D drawings from clients are seeing downward pressure on margins as they get cross-shopped for best price.

RPG Industries, Inc. Reinvent manufacturing by Metal 3D printing a vintage carburetor cap for a customer, which could not be sourced anywhere in the world and would be cost prohibitive to machine.

Why CNC shops are turning to Markforged;

☑️Improved image of the business

☑️Increasing customers (new+existing)

☑️Reducing Labour Costs

☑️Increased innovation capacity

☑️Automation with ability to print from the cloud anywhere in the world

☑️Digital Inventory

☑️Part count reduction

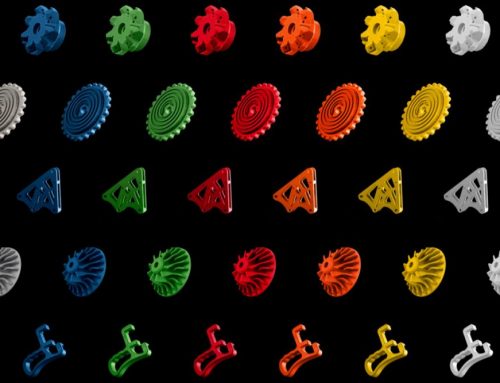

☑️Unparalleled design freedom

Request a demo!

Feel the strength of continuous fiber for yourself.

Leave A Comment