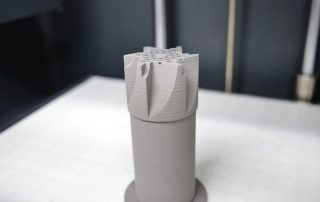

PTZ prints copper tool coolers with the Markforged Metal X

PTZ Prototypenzentrum GmbH in Dresden has been producing prototypes in metal and plastic for the most diverse industries for over 20 years. PTZ has a lot of experience with various additive manufacturing processes. For particularly demanding applications, no solution was found - until the components could be manufactured additively on the Metal X. This [...]