Description

The Markforged X3 – Uncompromising Power, Precision & Beauty.

The Markforged X3 is the most powerful 3D printer on the market. With the industrial pressure of incredibly strong parts and the first precision sensor systems, the Markforged X3 becomes an indispensable printer for every manufacturer. Take advantage of Markforged’s unique build-as-designed sensors and the beautiful finish of Onyx. Double strength of common standard plastics and a sophisticated sensor unit combine to provide unrivaled reliability. The Markforged X3 will enable you to make any design concept a reality.

[Embed] https://www.youtube.com/watch?v=odcaLfivg8c [/embed]

High Resolution Large Format Printer – For Best Printing Results

The large volume of the Markforged X3 makes it ideal for robotics, auto parts, functional prototypes and small batches. With a layer height of 0.05mm, your parts will come out of the printer with a beautiful surface finish that approximates the look and feel of injection molding.

Printing parts with maximum stability

The X3 3D printer delivers unparalleled strength, rigidity and durability in its printed parts.

[Embed] https://www.youtube.com/watch?v=QIoJyor54to [/embed]

touchscreen interface

Markforged’s X3 3D printer has a built-in touchscreen that makes it easy to control the wireless connection, start printing, and manage the printer.

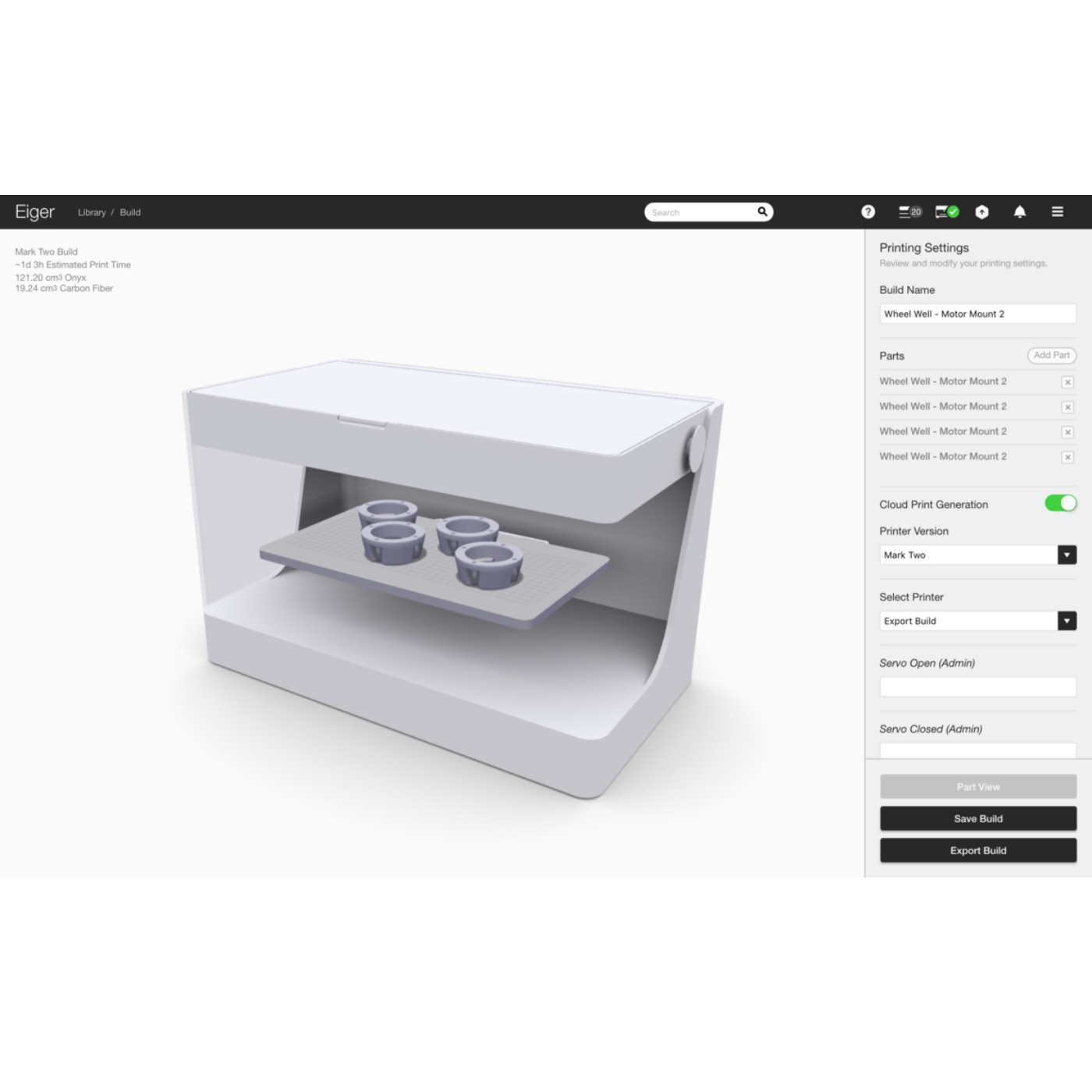

The Eiger Software

An innovative, stable or, above all, easy-to-use platform designed to reduce the user’s workload as much as possible. Furthermore, the EIGER software is cloud based, which means that the software is always up to date. From your PC, you can load the 3D print jobs into the cloud-based EIGER software via your browser. The 3D printer can be controlled via LAN cable, USB and W-LAN. The software allows you to manage and catalog your STL files.

Thanks to the ease of use, you can intelligently provide your component’s interior with support structures and completely automatically furnish layer by layer in the selected region of the component with the endless fiber. The fibre density can be changed per layer via a simple slider in the software. Thus, you can design your component perfectly to your force and print out.

The printing process can be paused to embed components in the print. You can thus integrate electronics, sensors and ball bearings into your component.

Optionally, we also provide an EIGER OFFLINE version. Here is another charge.

& nbsp;

DELIVERY

- 1x X3 3D Printer

- 1x dry box

- 1x Onyx FFF filament 800cm³ roll

- 3x FFF replacement nozzle

- 1x tool set

- 1x Build Platform True Bed X-Series

Do you have more questions?

Send us an

email or use the

Chat .

You can also call us Tel: 0800 190 3650

Browse our entire article overview

If you can’t find what you’re looking for you can

‘get-in-touch’

Reviews

There are no reviews yet.