Avoid threads on your 3D-printed components

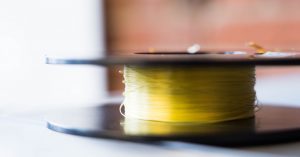

Under certain circumstances it may happen that your 3D printed component does not correspond to the desired or usual quality. The reason for this is often a lack of maintenance of the printer or incorrect storage of the materials. If the result of your 3D printing is unsatisfactory, it is imperative that you investigate the cause and find out why the component does not meet the usual excellent print quality. This is the only way to avoid mistakes in the future and to print your components at the highest level.

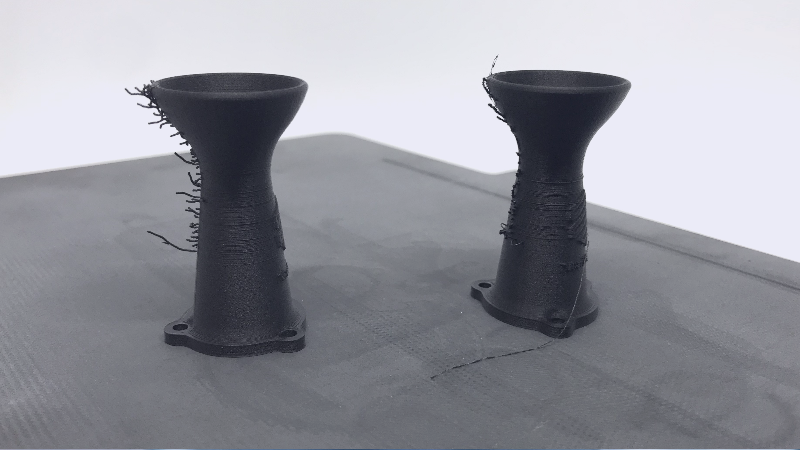

With the Markforged Desktop series, the printer checks its position at 5 layer intervals by performing a reference run to the zero point (back right). This results in an excess of material, which the printer deposits in the form of threads when it is reattached to the component.

The “settling” of the material is most likely caused by damp material. To check whether damp material is the reason for the unaccustomed quality, please carry out the following tests.

The pause test

With Markforged 3D printers, you can pause printing at any time. As soon as you press the “Pause” button on the display, the print head moves to its “park position” at the back left. Now you have to take a look at the nozzle. NO material should leak out there. In the video you can see how material comes out of the nozzle = material damp:

Material runs after (damp material)

Material runs not after (dry material)

The buckling test

Another way to check the moisture of your material is the “buckling test”. Here you take a piece of the filament and break it off. If the filament can be broken off, it is dry. If it bends, it is damp.

How can I avoid damp material?

If your material has become damp, we recommend that you replace the roll. Because you can only achieve perfect results with perfect material.

Unfortunately, we cannot guarantee high quality printing results if the material is not dried properly.

It is particularly important that hygroscopic material is always stored in the dry box with the silica gel packs and that these are securely closed. Otherwise the material can absorb moisture from the environment. Please make sure that the silica gel packs supplied with the material are always placed in the drying box. When exchanging the material roll, the following applies: Old packages out and new packages in.

Once you have made sure that your material is stored dry, unsightly threads on the component should be a thing of the past and the quality should meet the desired requirements.

Difference in print quality at a glance:

Damp material

Dry material

Should the print result still not be as desired, you will find further help in our SUPPORT-Center or from our support staff:

E-Mail: printstronger@mark3d.co.uk

Phone: +44 121 222 5510

![Jet Dragster Racing [Video] with 3D Printed Parts](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/Josette-Roach-500x383.png)

![Hollywood Propmaster [Video] 3D Printing with Markforged](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/Thingergy-26-scaled-500x383.jpg)

![BattleBots Valkyrie [Video] Using 3D Printed Parts](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/BattleBots-11-500x383.png)

Leave A Comment