#13 Road to Christmas – Dixon

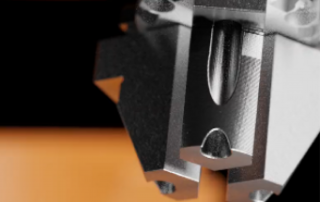

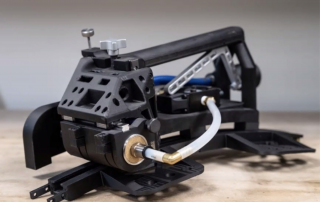

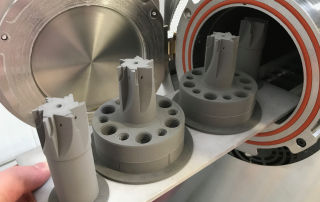

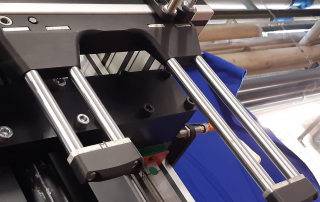

#13 Road to Christmas – Dixon 3D printing with exceptional surface finish! 💪 „These jaws are hard enough to process thousands of stainless steel pipe couplings without wearing down.“ – Dixon Valve ✔ 91 % time savings ✔ 98 % cost savings ✔ Optimised construction for maximum grip Read the whole Case Study [...]