Probably the world’s best 3D printed racing drone

3D designer Stefan Obermayr has designed – specifically optimised for the Markforged series – a racing drone frame that is both extremely lightweight, aerodynamic and yet practically indestructible. He has incorporated his decades of experience in model making and 3D design to create the perfect racing frame. The result is an extremely uncluttered concept that can withstand any collision and still offer high-performance flight characteristics.

“Only the best components were used to create probably the best 3D printed racing drone in the world! Racing drones have to withstand brutal collisions at significant speeds on a regular basis without failing afterwards. The race must go on!”

Conventional racing drone frames consist of several individual components milled from carbon fibre composite panels and bolted together. The design of such frames always compromises strength, weight and aerodynamics. The wider the CFRP panel, the stronger the frame, but both take-off weight and aerodynamics suffer. If the frame is highly optimised for take-off weight and aerodynamics, it inevitably becomes more susceptible to collisions.

The optimal design of a racing drone frame consists of only one part, is extremely light, has streamlined arms and is also highly collision resistant.

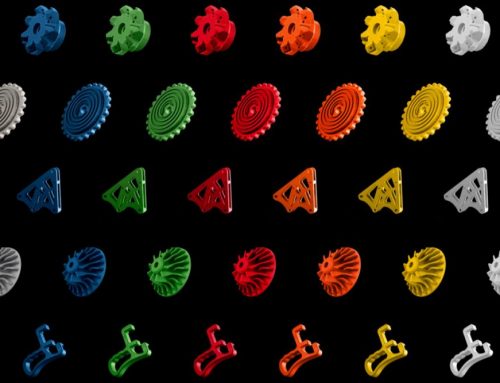

The solution to the problem is 3D printing with carbon continuous fibre reinforced plastic in lightweight construction using Markforged’s 3D printers. Each continuous fiber is placed exactly in the direction of stress and only at the exact points where forces actually act. In this way, each individual fiber contributes to the stability of the overall structure.

The interior of the structure can be made largely hollow – and conveniently conceal the necessary motor and supply lines, which would otherwise often be damaged in the event of a collision due to the very fast rotating propellers.

Request a demo!

Feel the strength of continuous fiber for yourself.

Learn more about 3D printing continuous fibres!

Which continuous fibre is suitable for which applications? How do I design correctly for filament 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.

Leave A Comment