Leasing: Simply uncomplicated

The Markforged 3D printers in our monthly leasing offers. Benefit from plannable rates with full cost control.

Get a competitive edge with Markforged 3D printers without investing a lot of capital and resources in the purchase!

With our leasing offers, you benefit from the unique technology without having to tie up any capital

Albis Leasing

As a leasing partner, we work successfully with the Albis Leasing Group.

With over 35 years of experience in the leasing market, Albis is an expert in the field of leasing and hire-purchase and is perfectly suited to your leasing.

Do you have any questions? We are happy to help! Here you will find the most frequently asked questions:

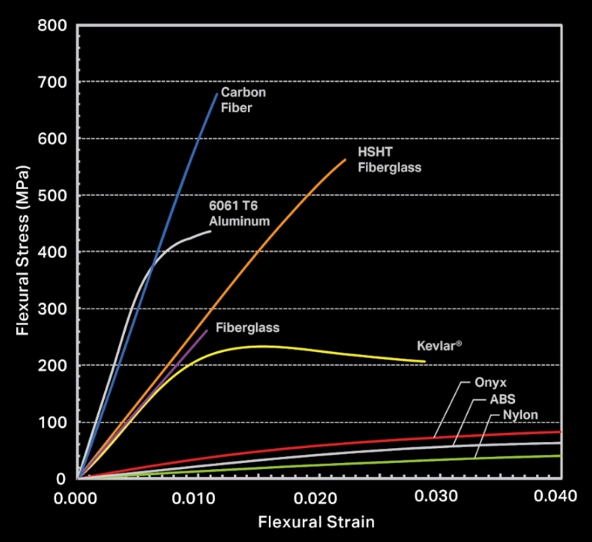

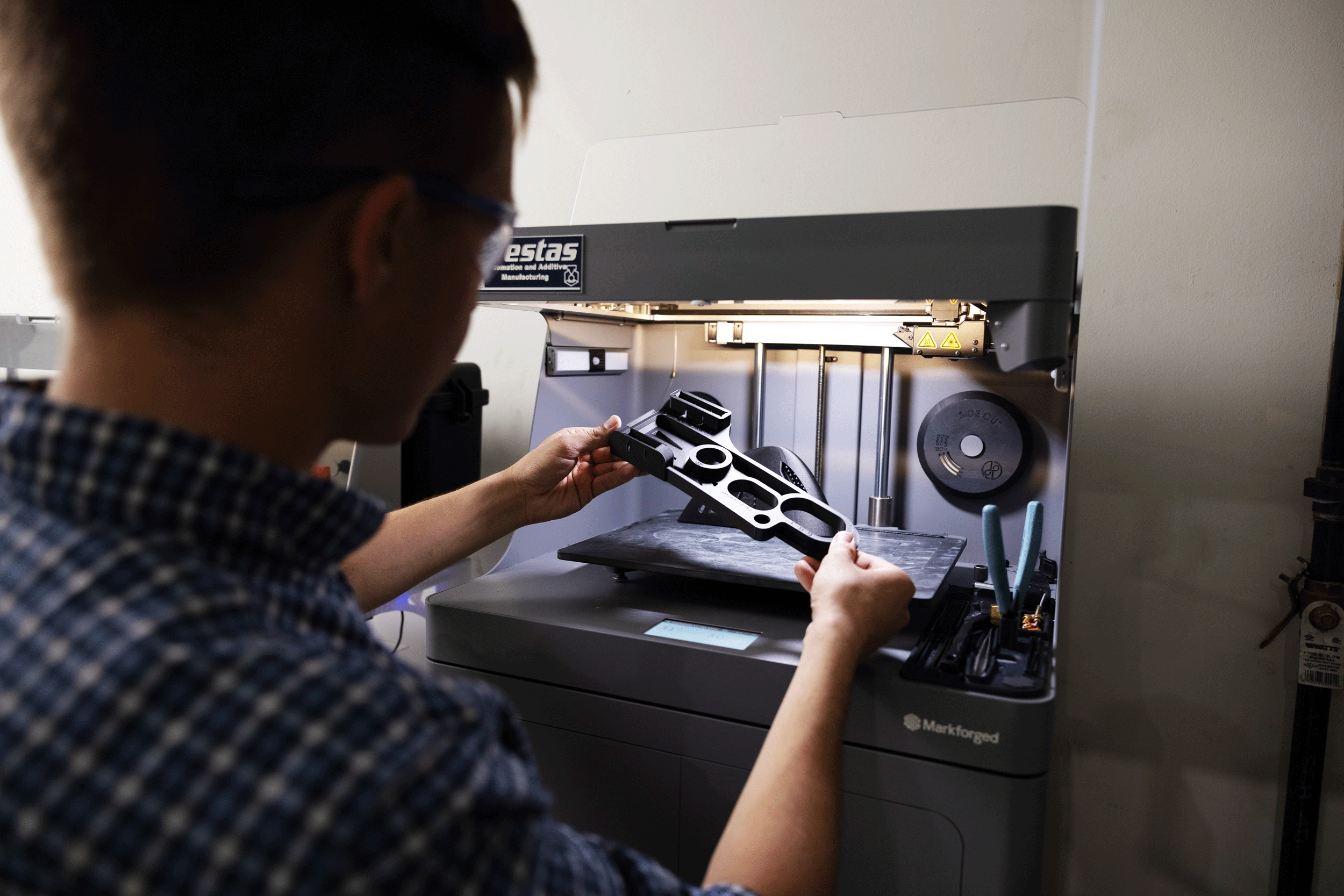

Some 3D printers are known for their ease of use and ease of use, others for making beautiful parts with a great finish, and still others for the strength of the parts they can print. Luckily, if you’re looking for a perennial favorite that can produce high-strength parts with a great surface finish, easily and without much 3D printing experience, an industrial markforged 3D printer is a good choice.

We’ve put together a few key points you should know:

Learn more about metal printing applications!

For which applications is the Metal X suitable? How do I design correctly for metal 3D printing? What do users say about this and where can I find more information? – You’ve come to the right place! We have listed some information options that will take you straight to the right answers.

Submit a request for a lease offer for a Markforged 3D printer now.

Mark3D UK Limited The Innovation Centre 1 Devon Way, Longbridge, Birmingham, B31 2TS

Phone: 0800 193 3650 E-Mail: printstronger@mark3d.co.uk

World’s leading companies use Markforged 3D printers

Um mit uns in Kontakt zu treten, füllen Sie bitte unser sicheres Formular aus.

Oops! We could not locate your form.