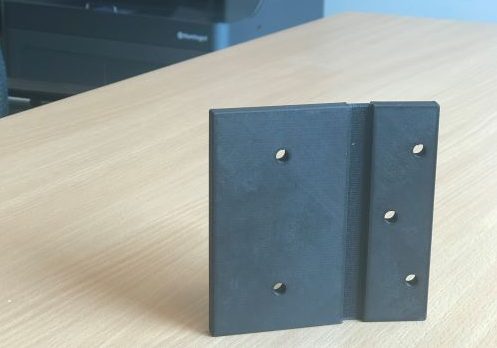

This blog takes a look at how to print a living hinge, which are really simple and very robust. We’ve bent ours literally thousands of times and it doesn’t show any signs of wear or discolouration. There are plenty of applications which suit it very nicely, such as rugged cases, electrical control boxes, enclosures and general protection equipment. We’re continually impressed by Onyx as a printing material – each time we test it on a new application it surpasses our expectations.

We perfected our hinge by running a few tests to find the optimum thickness. We also discovered it’s possible to make left handed, right handed or universal folding actions. We also did a weight comparison and it comes out very favourably indeed when compared to a similar printed hinge that requires a steel pin.

There are a couple of other things you should consider if you are going to try printing one:

1. Hows stiff do you want the hinge action to be – this is controlled by thickness.

2. How many ‘cycles’ does the hinge need to perform throughout it’s life – this may impact on thickness too.

3. Where your support materials goes – if you think about it beforehand you can make sure the supported surface ends up inside the fold when the hinge is actioned.

4. You can print hinges that are permanently closed (the default action is to spring back to shut) or in a neutral position – this will sometimes dictate the orientation on the print bed.

5. Do you want a left hand, right hand or universal hinge?

If you would like to know anymore about printing living hinges you can give us a call on 0800 193 3650 or take a look at the printer this was produced on.

Leave A Comment