CNC vs. 3D Printing

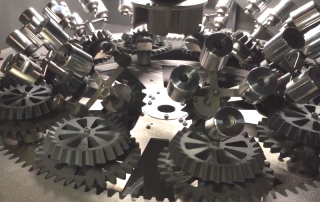

CNC vs. 3D Printing:What's the best way to make your part? Introduction The development of stronger 3D printing materials has encouraged manufacturers across industries to explore CNC vs 3D printing, and find ways to 3D print functional parts that were previously CNC machined. The 3D printing process can save manufacturers considerable [...]