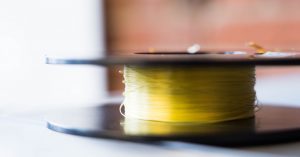

Why does a manufacturer of subtractive cutting tools rely on metal 3D printing? 🤯

Is metal 3D printing a complement to CNC machining or a competition?

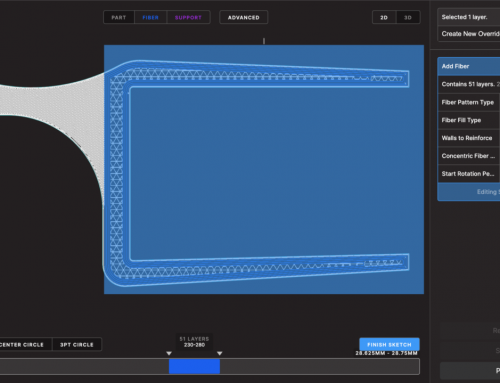

This video dispels some prejudices and is a great insight into a cutting tool made with the Markforged Metal X system.

Does the part withstand 10,000 rpm and the machining of aluminium?

Guhring UK has proven that the use of both technologies together gives the following benefits:

✅ Lighter weight tool

✅ Cheaper prototyping

✅ Lower costs for small series

Additive manufacturing and traditional machining probably go together better than most people would have expected.

A 3D printed PCD cutting tool in conventional manufacturing! 🤔 What do you think about it? Is this what the future looks like? Write it in the comments ⤵️

Request a Sample Part!

Feel the strength of continuous fiber for yourself.

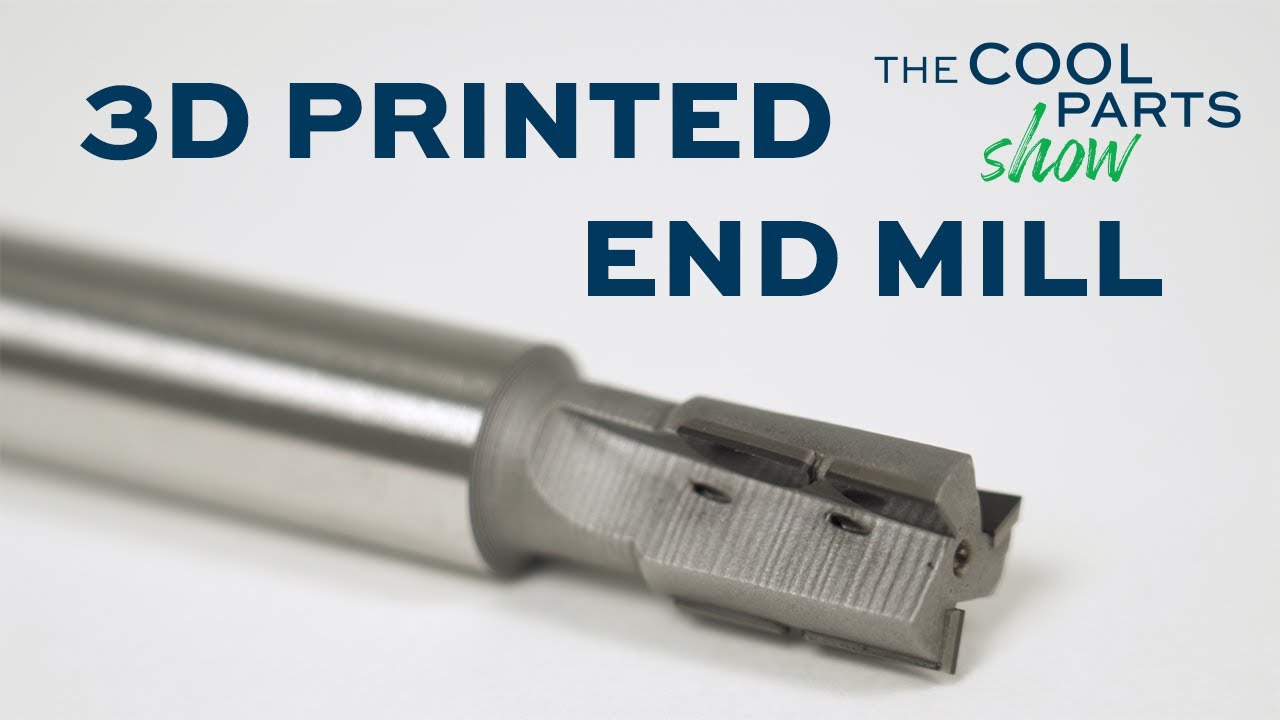

Learn more about applications with metal 3D printing!

For which applications is the Metal X suitable? How do I design correctly for metal 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.

![Jet Dragster Racing [Video] with 3D Printed Parts](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/Josette-Roach-500x383.png)

![Hollywood Propmaster [Video] 3D Printing with Markforged](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/Thingergy-26-scaled-500x383.jpg)

![BattleBots Valkyrie [Video] Using 3D Printed Parts](https://www.mark3d.com/en/wp-content/uploads/sites/6/2024/01/BattleBots-11-500x383.png)

Leave A Comment