We had some exiting news from Markforged last week with the announcement of their expansion into mass production of end-use metal parts. Markforged are set to acquire Digital Metal, the creator of a leading binder jetting solution known to be precise and reliable.

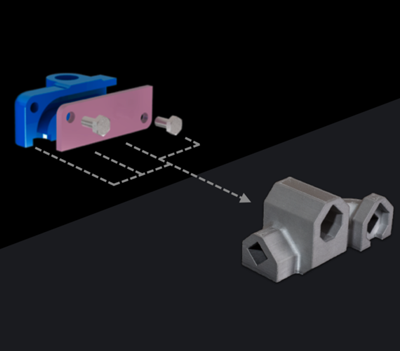

The Markforged Metal X system is a popular choice for accessible, end-to-end metal printing, used for low volume production, R&D and within education. Markforged are already well known for quality and reliability, making Digital Metal a strong addition to the line-up. We’re exited to see this technology incorporated into the Digital Forge and extend capabilities into high-throughput production of metal additive parts.

Watch this space for further updates and read the full announcement on the Markforged website here.

Learn more about applications with metal 3D printing!

For which applications is the Metal X suitable? How do I design correctly for metal 3D printing? What do users say and where can I find more information? – This is the right place for you! We listed some information leading you directly to the matching answers.

Leave A Comment