We’ve been talking about inserts a lot this week at MarkForged. The ability to add embedded hardware is one of the aspects of additive manufacturing that strongly differentiates it from traditional manufacturing methods. You can add magnets, RFID chips, hardware controllers or many other types of embedded hardware.

A part Dan likes to use to demonstrate this ability during MarkForged training is a Kevlar® reinforced letter opener. This is a great demonstration part because it only takes about 4 hours to print and only uses about 5 cubic centimeters of nylon and 5.7 cubic centimeters of Kevlar®.

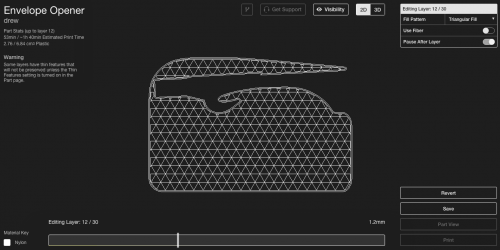

Pausing the Print to Embed Hardware

The MarkForged software allows you to insert a pause at the top of the cavity for the embedded hardware. In this case, we put the pause at layer 12. Then the printer will finish the part completely embedding the razor blade.

With the Pause After Layer toggle on, the printer will stop at that layer and notify you that it’s ready for the insert. This notification will be displayed on the Touchscreen and via the MarkForged software.

The printer will wait until you press the continue print prompt on the touchscreen. This will resume the job and finish the part. Then you can use the opener to simultaneously demonstrate your composite printer, get through your mail and also comparing the stiffness to a traditional, metal letter opener.

Specifications

Kevlar® Reinforced Letter Opener

Size 81.36mm x 53.84mm x 2.96mm

Estimated Print Time ~4h 11m

Nylon Cost $1.05

Carbon Fiber Cost $6.86

STL Download Envelope-Opener.stl ()

MFP Download Envelope-Opener-Kevlar.mfp ()