You may have noticed already that Carl Calabria keeps things organized here at MarkForged. He keeps the tools clean and organized; this both increased productivity and sets the tone for a clean, organized company culture. Carl is also a fan of constantly improving, so he designed this part to both organize the tool set used to maintain a Mark One 3D printer and to improve his additive manufacturing skills.

This Mark One Maintenance Toolset Caddy contains all the bits and sockets used to service a Mark One 3D printer. It also includes two different types of inserts including 12 magnets to keep the bits in place. The inserts were added during printing using the pause function of the MarkForged printer and software.

A Step by Step Guide to Adding Inserts

- CAD the caddy in OnShape, leaving cavities for the razor blade and 12 magnets in OnShape

- Export from OnShape as a STL

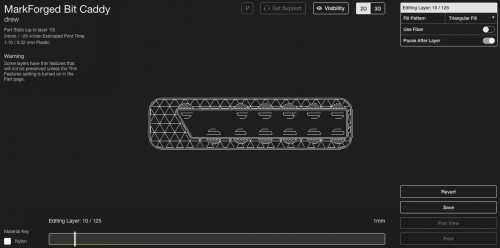

- Import the STL into the MarkForged Eiger Software

- Click Part View

- Click 2d view

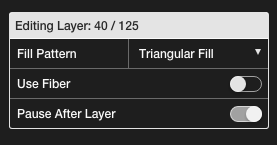

- Add pauses at two points

- Click pause after layer at the upper right

- Start the print and stare in wonder as the build starts

- When layer 10 pauses, insert the razor blades, with a thin layer of glue stick applied to the top of the razor blades

- Click resume print on the touchscreen

- Add some glue over the magnets, to ensure adhesion

- Click resume print on the touchscreen

- The rest of the caddy will print on top of the magnets

Notes

- The height of cavity should be the same size as the embedded part

- If cavities are taller, you’ll be printing in midair and can have a print failure

- If too short, the print head will bump into the inserts

- Glue on the inserted hardware ensures adhesion of the layer above the inserts

- Download the STL Here French Horn Case Study – PRT ()

- Download the MFP Here French Horn Case Study – PRT ()