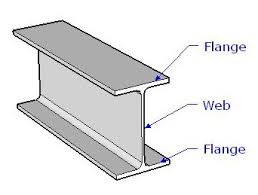

A Sandwich Panel is the composites version of an I-Beam.

I-Beams are common members for building because they are very efficient at carrying bending and sheer loads along the plane of the web. The Flange on the I-Beam carries the load, while the web transfers the sheer stress.

Metals beams are commonly used at a large scale, like buildings and load bearing frames. There is a composite equivalent that can be used at a small scale, the composite sandwich.

Introducing the Composite Sandwich

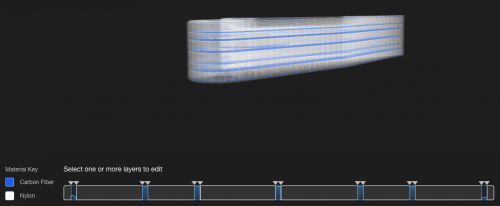

The sandwich pictured above has a top and bottom layer of traditional carbon fiber sheets. The carbon fiber forms the top and bottom of the panel and a lightweight honeycomb core forms the interior.

The majority of the load is resisted by the carbon. The honeycomb structure transfers the sheer stress between the top and bottom layers. The pictured panel has been created using a traditional epoxy layup.

The traditional method of creating carbon fiber adds a lot of strength but can limit the geometries and scales possible. It also requires the personal safety equipment, chemicals and space required by a traditional carbon fiber workflow.

The Easiest Way to Make Composite Sandwich Panels

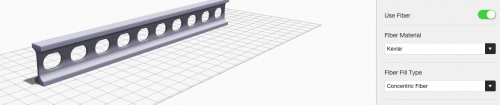

- Import Your Model

- Click the “Add Fiber” button

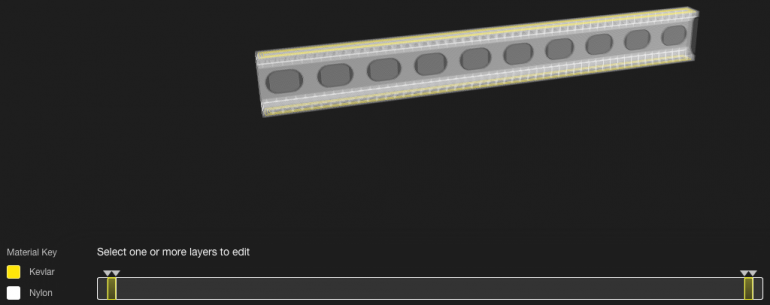

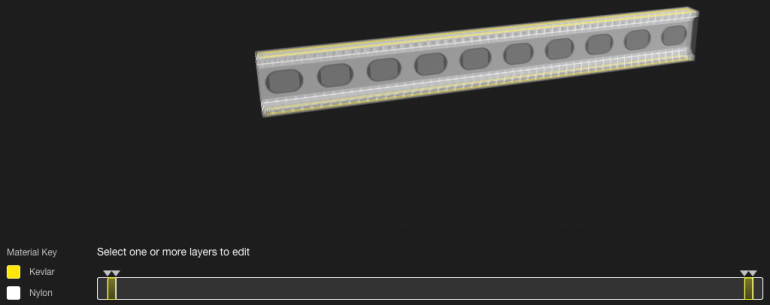

Eiger will automatically add fiber sections are at the top and bottom of the part. You can see the automatic sandwich panelling in the internal view.

In this beam example, the Eiger software has automatically added kevlar at the top and the bottom of the I-Beam model automatically. This creates a sandwich panel to maximize the strength to weight of the part.

If you want the part to be stronger, you can use the sliders to easily increase the thickness of the top and bottom fiber layers in the part. It is also possible to add a fiber layer to the middle of the part or increase the number of fiber layers at the top and the bottom.

Here is the jaw pictured above with two layers of fiberglass reinforcement. The layer placement was manually optimized to align with the knuckle joint in the part.