Fiber Reinforced 3D Printing Provides Military-grade Toughness for the Genasun-II CM

When the U.S. Marine Corps needed a way to guarantee the life of their most ubiquitous field battery, Genasun was ready to upgrade their fail-proof, solid-state MPPT solar charge controller into a field-ready portable charger for the Corps’ workhorse BB-2590 Lithium Battery.

Rapid prototyping is a way of life at the Marine Corps Warfighting Laboratory (MCWL) at Quantico. Genasun were able to impress their customers with a quick turnaround with a shock-resistant enclosure design in 3D printed ABS. The only problem was that the enclosure design couldn’t be field tested.

3D printed ABS electrical enclosures simply weren’t rugged enough to stand up to in-theater testing. 3D printing was the right solution as it quickly allowed fast iteration and fit testing of the electrical components. The printed parts just needed to be stronger – Marine Corps Strong.

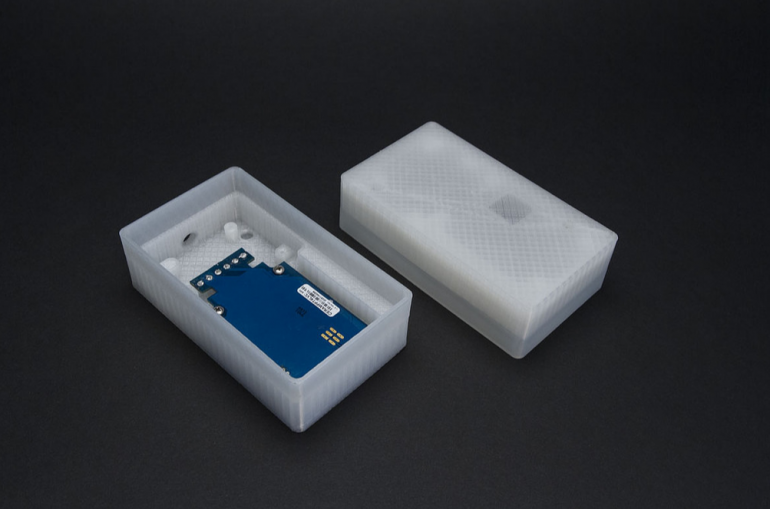

Caption: “3D printed ABS GI-2590 solar charge controller”

Nylon + Kevlar® = Strong Enough for the Corps

The same enclosure printed by the Mark One Composite 3D printer in Nylon with Kevlar® reinforcement was strong enough. The composite printer created a reinforced electrical enclosure with the toughness and impact resistance of nylon combined with the strength, stiffness, and light weight of continuous strand Kevlar®.

Caption: “3D printed Kevlar reinforced Nylon GI-2590 solar charge controller”

“It’s clear the parts printed with the Mark One Composite 3D Printer can be drop tested, field tested, or even thrown out of a helicopter. The Mark One’s base Nylon 6 copolymer is a classic solution to impact resistance and snap fit applications, but now with Kevlar throughout, we can test it any way we like.”

Fiber reinforced parts printed on the Mark One can be field-ready right off the printer to house mission-critical equipment like the BB-2590, which powers field radios, night vision systems, and bomb disposal robots. Not only are the prototypes strong enough to survive testing but the materials are familiar enough to convince Marines who already know and trust Kevlar®.

How did Kevlar® Reinforced Nylon CFF compare?

| Method | Cost | Time |

|---|---|---|

| Service Bureau Nylon 6/6 (30% glass fill) | $570.88 | 3-5 business days |

| Service Bureau Nylon 6 | $263.87 | 3-5 business days |

| Reinforced 3D Printing Nylon 6/Kevlar® | $49.31 | 24 hour print time |

Today Genasun is using the Mark One to create more rugged prototypes that both showcase the range of opportunities available, the speed of iterating with 3D printing and strength to withstand even the most rigorous testing.

The Kevlar® reinforced GI-2590 solar charge controller prototype also paved the way for other 3D printed composite prototypes.