Tony fired up TinkerCAD to create solutions to those two problems:

- A nylon spool for testing small amounts of continuous carbon fiber, Kevlar TM and fiberglass.

- A tiny tool rack for holding the most used Mark One tools: the glue stick, tweezers, allen wrench and leveling shims

The nylon spool is 100 mm diameter by 21 mm. It functions as a spare spool, mostly used for testing new runs of fiber but also as a way of creating some visual symmetry with the other composite material wheel.

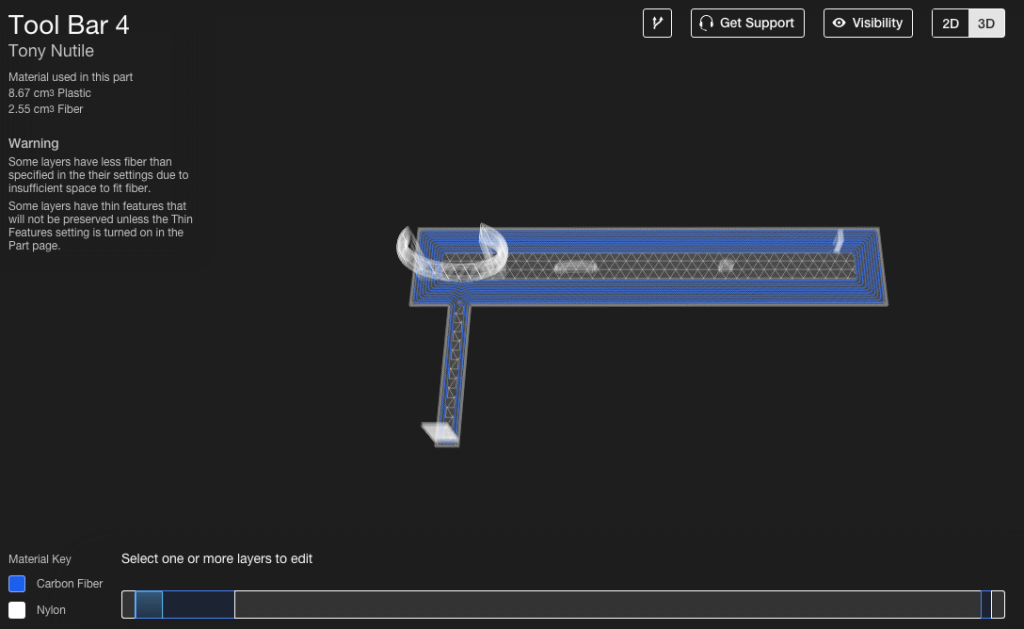

The tool caddy is reinforced with carbon fiber. Notice how the software is updating the slices to optimize the carbon reinforcement. The other tooltip is recommending settings to use to optimize the print to maintain tiny features with dimensional accuracy.

You can also see the accessory set on Thingiverse.

Specifications

Spare Spool

Size 100mm x 100mm x 21mm

Estimated Print Time ~24h 0min

Nylon Cost ~$3.10

STL Download MarkForged_Tonys_Spool_4.stl ()

Tony’s Tool Bar

Size 160.5mm x 78mm x 32.29mm

Estimated Print Time ~2h 32min

Nylon Cost ~$1

Carbon Fiber Cost ~$2

STL Download French Horn Case Study ()